History

Seydelmann Custom Center

The Seydelmann Customer Center opens its doors. A place of meeting between customers and Seydelmann technologists was created at the production site in Aalen in summer 2023. This is where development takes place in real time. Like a modern food processing plant, the customer center was fully equipped with all machines for upstream and downstream food production processes. The new customer center meets the highest hygiene requirements and has EU approval for food production. Together with the customer, Seydelmann food technologists work on product developments as well as quality and efficiency improvements. For the customers this offers the advantage to experience their products directly on Seydelmann machines, such as cutters, grinders, mixers and fine shredders - for us the chance to align the development process even more specifically to the requirements of the respective customer and to optimize processes. There is an open meeting area with a catering kitchen for the preparation of the produced goods and also extensive laboratory equipment for the scientific analysis of food products. Tasting and handing over of the produced food products to the customer is guaranteed.

IFFA 2022

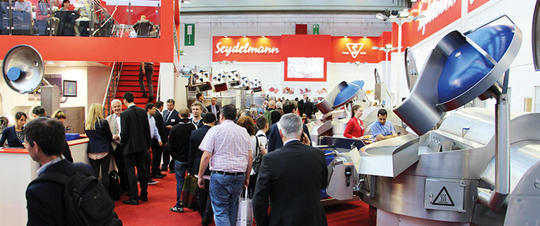

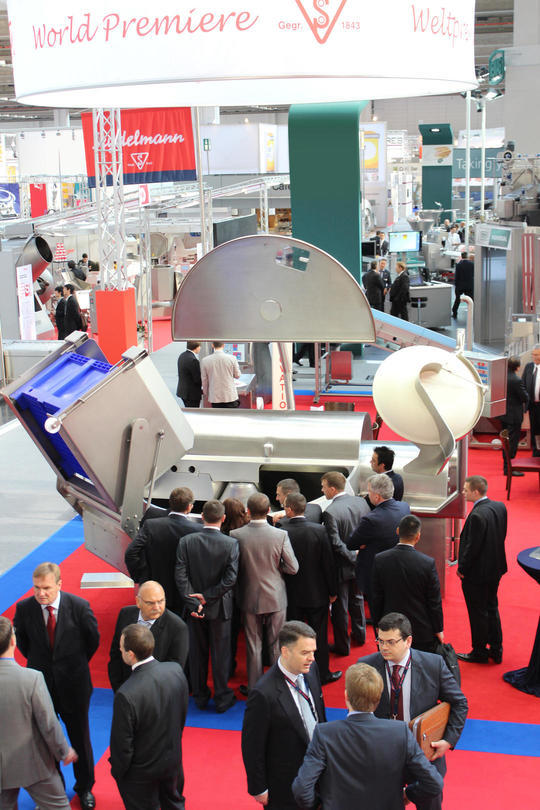

On more than 1,000 square meters of booth space, Maschinenfabrik Seydelmann KG presented visitors with more than 50 machines and two fully automated production lines for the production of meat and meat alternatives.

In the IFFA Factory, a completely set-up production line, a meat product and a plant-based product were alternately produced on site. Experts moderated the entire process live and provided information on recipes, ingredients and processes.

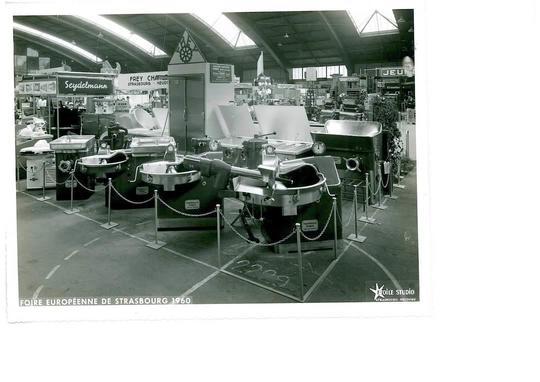

At the museum booth, historical machines, as well as art works from the butchery trade, were exhibited in cooperation with the German Butcher Museum in Böblingen.

At the booth party on the 2nd day of the trade fair, the day was brought to a close with rotisserie chicken, finger food buffet and cocktails.

IFFA Innovations 2022

The family of emulsifiers has grown. With the newly developed Vacuum-Konti-Kutter KK 144 AC-6 Seydelmann now offers its customers the entry into ultra-fine emulsifying with vacuum technology for medium production quantities. Emulsifying under vacuum results in a more compact sausage meat with constant volume weight and increases the shelf life of the final product. Higher protein extraction is achieved and better color stability is obtained. The cutting set operates frictionless and thus without metal abrasion. Due to the low overall height and compact design of the KK 144 AC-6, the hopper can be placed under the outlet flaps of a mixer or under the cutter ejector, thus integrating the machine directly into the product flow is possible.

IFFA Innovations 2022

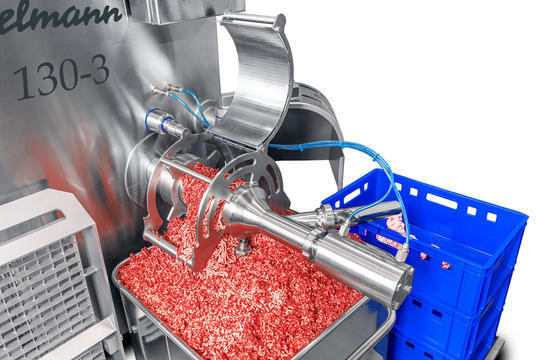

The completely revised and newly designed Universal Grinder AW 300 U of the second generation with higher hourly output, lower energy consumption and even better particle definition, now has the grinder outlet on the right side, as all industrial grinders from Seydelmann. Like the AU 200 U, it has a cleaning hatch and removable bearing for the feeding worm. The hygienic design has also been further improved in other areas. For example, CIP connections facilitate cleaning of the main bearing seal and the machine stand is designed without hollow bodies, such as tubes or closed profiles. Polished, sloped surfaces facilitate cleaning. A swiveling crane for the grinder nut improves ergonomics and relieves the operator during cleaning and cutting set change. The worm design has been optimized and thus, together with the intelligent control system, the hourly output of the AW 300 U has been increased - regardless of whether fresh meat or whole frozen meat blocks with a temperature down to -25 degrees Celsius are being processed.

IFFA Innovations 2022

The Seydelmann Cutting Drum ensures the efficient separation of hard parts and foreign bodies such as plastic particles or foil residues. The system, consisting of a perforated drum and an extended working worm, allows, compared to conventional cutting sets, a higher throughput and thus hourly output at a lower input temperature. In addition to the already existing sizes E 130 and G 160, it is now also available in the outlet size U 200.

IFFA Innovations 2022

In the Trolley Tumbler, the standard trolley filled with the products to be mixed serves as the mixing container. Loading and emptying of the machine, as with conventional mixers or tumblers, is not necessary. This allows fast product changes and minimizes product losses. Depending on the machine design, mixing is performed by horizontal or cross rotation - if desired, also under vacuum. Simple operation and easy-to-understand controls reduce personnel requirements: only one person is needed to operate the machine. Maximum operating safety is ensured by the protective fencing with monitored safety door and the laterally positioned and moisture-protected electronics.

IFFA Innovations 2022

All Vacuum-Cooking-Cutters of Seydelmann have been revised and further improved especially with regard to automation and hygienic design. For example, the seal in the lid for sealing the bowl is now removable and adjusts itself. This simplifies cleaning and eliminates the need for time-consuming adjustment work when replacing the seal. The pipes and nozzles of the bowl heating/cooling system are made entirely of stainless steel. The machine frame is now ventilated with positive pressure to exclude the ingress of dust or moisture.

2nd International Seydelmann Sales Meeting

More than 165 guests from almost 60 countries accepted the invitation of Maschinenfabrik Seydelmann KG. For two days the innovations of the last three years were presented in seven workshops and numerous lectures to bring the representatives from all over the world up to date and to prepare them optimally for the IFFA which followed directly afterwards.

Foundation of the SCT Vorndran GmbH

Maschinenfabrik Seydelmann KG acquires Vorndran Industrieverschleißteile e.K. and founds SCT (Seydelmann Cutting Tools) Vorndran GmbH. This way, Seydelmann expands the secure supply of spare and wear parts for its customers and further increases the innovative strength of the company.

For more than 30 years, Vorndran has been producing and developing wear parts for food processing made of metal and plastic with 14 employees in Münnerstadt. The focus is on cutting set parts for grinders and forming, portioning and packaging tools.

Foundation of the SCT Fuchs GmbH

Maschinenfabrik Seydelmann KG acquires J. F. Fuchs Maschinen- und Werkzeugfabrik GmbH & Co. KG and founds SCT (Seydelmann Cutting Tools) Fuchs GmbH.

With the traditional Stuttgart company founded in 1830, J. F. Fuchs Maschinen- und Werkzeugfabrik GmbH & Co. KG, Seydelmann takes over 20 employees and over 190 years of know-how and innovation in the production of cutter knives. The company is one of the largest producers in this field. The complete manufacturing process is handled in-house. Regrinding is also part of the company's portfolio. The high vertical range of manufacture will also be maintained in the future. This will expand the secure supply of spare and wear parts to its customers and further increase the company's innovative strength.

SÜFFA 2021

Large crowds and an interested and qualified audience - this is how the SÜFFA 2021 at the Seydelmann booth can be summarized in a few words. Despite lower exhibitor numbers and somewhat fewer visitors, the trade fair has once again proven its high value. In addition to the wide range of machines on display, the latest hygiene design on cutters and the lifting devices for E2 crates on cutters and grinders at the stand of Maschinenfabrik Seydelmann KG acted as additional crowd pullers.

Completion of new line assembly

After less than 5 months of construction work, the new building for production lines is completed. The new production hall was opened during a small reception with the Lord Mayor of the city of Aalen Thilo Rentschler, the mayor Wolfgang Steidle, the head of the staff department for economic development Felix Unseld as well as representatives of the press and the company's managing directors Andreas Seydelmann and Matthias Seydelmann.

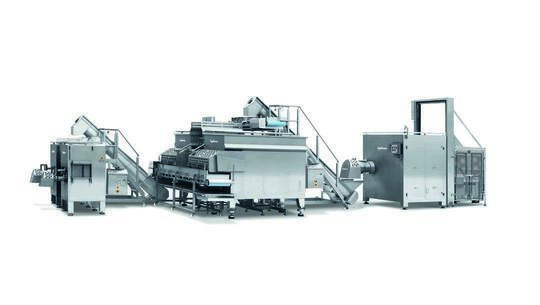

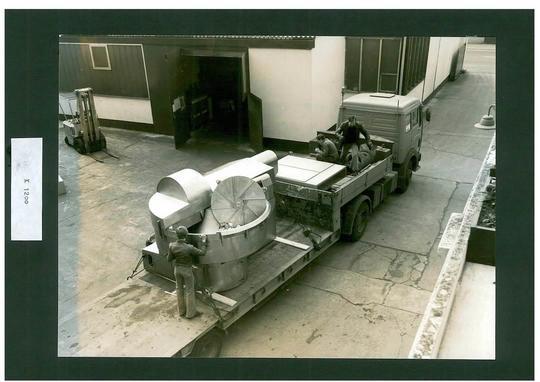

Largest order in the company's history

The largest order in the company's history is delivered to the customer on 24 trucks. Around 206 tons of stainless steel are sent on their way. The complete sausage production plant consists of four fully automated lines with a total of 49 machines including associated conveyor technology and will occupy an area of 1,100 square meters.

Start of new building line assembly

Start of construction of the line assembly hall on the expansion area acquired in 2017. A new production hall and storage areas will be built on a total of 2,000 square metres to meet the space requirements of the rapidly growing business area of fully automated production lines. The new hall will be built using sustainable construction methods with plenty of natural light and a green facade.

In order to cover the increased energy demand, the roof of the new machining shop, which has been commissioned in 2016, will be fitted with a photovoltaic System.

Foundation Seydelmann Conveying Systems GmbH

Through the participation in the GEST Edelstahltechnik GmbH and the subsequent change of name the SCS GmbH (Seydelmann Conveying Systems) is created. The new subsidiary concentrates on the area of plant and conveyor technology and pushes the development and production of the conveyor systems of the Seydelmann production lines.

IFFA Innovations 2019

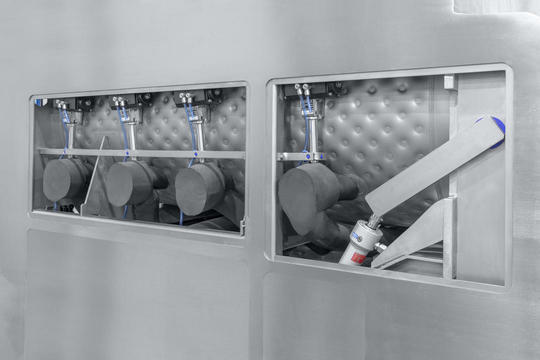

For indirect cooling with water or glycol or for heating with water or steam, so-called pillow plates are now available for all mixers, vacuum mixers and mixer-grinders. They allow the temperature to be controlled or maintained during mixing. The product remains free of extraneous water and this solution is more cost-effective than direct temperature control of the raw material.

IFFA Innovations 2019

The feeding worm is equipped with a removable bearing to facilitate cleaning.

IFFA Innovations 2019

Also new in the product portfolio is the cutting drum for meat. This cutting system for fresh meat works completely without knives or hole plates. This means there is no metal abrasion and hardly any wear. The maximum warming of the material to be cut is 3°C. Depending on the hole size, up to 100% of cartilage, tendons, bone splinters and other foreign bodies are sorted out.

IFFA Innovations 2019

The newly developed feeding storage enables the integration of cutters into production lines and a continuous material flow. Thus, all advantages of the cutter can be used and high hourly outputs in (fully) automatic operation can be achieved.

IFFA Innovations 2019

The new Mixer-Grinder AMR 3500 has a hopper capacity of 3500 l and a mixing capacity between 400 and 2200 kg. It enables high hourly outputs for the constantly growing area of burger and minced meat production with optimum material mixing and a clear cutting.

IFFA Innovations 2019

The powerful Universal Grinders AU 200 U and AV 250 U present themselves in the latest generation. They can be used regardless of the starting temperature of the raw material. They grind fresh meat, whole frozen meat blocks down to -25 °C and other materials simultaneously or separately, regardless of consistency and temperature.

1st International Seydelmann Sales Meeting

On the occasion of the 175th anniversary, the 1st International Sales Meeting takes place at the plant in Aalen, where all international representatives of Maschinenfabrik Seydelmann KG come together to participate in workshops in different areas, to exchange ideas and to learn about success stories of the different partners.

Participation BEGARAT

Through the cooperation with BEGARAT VERTRIEBS- UND SERVICE GmbH, sales and service in Russia are reorganized. With Begarat an experienced and already longtime active partner on the Russian market was won.

Company party

On the occasion of the 175th anniversary, a large employee party was held on July 21, 2018 with around 325 active and over 100 former employees from Aalen and Stuttgart and their families. In organized factory tours, the guests were able to visit the entire premises with the different production areas, various food trucks were available for catering and there was also a lot on offer for the kids.

There was a fun atmosphere in the large tent, where the long-standing success of the traditional company was celebrated together.

175th anniversary

Founded in 1843, Maschinenfabrik Seydelmann KG celebrates its 175th anniversary in 2018. Today, it is the world's leading manufacturer of food processing machinery and is in its sixth generation of family ownership. Much of what is standard in the food industry today was developed by Seydelmann in Aalen and Stuttgart.

SÜFFA novelty 2018

With the new lifting device for the common Euronorm meat crates (E1, E2, E3), the improvement of ergonomics in the trade is pushed forward. The optional additional equipment for cutters and grinders relieves the back of the machine operator and additionally leads to time savings. If the lifting device is no longer required, it can be folded upwards and locked in place.

Expansion of the production area

The production and storage areas are significantly increased by the purchase of adjacent areas and buildings of the former Egelhaff tissue paper mill. The existing factory buildings have been modernized and serve as storage for about 600 electric motors and frequency converters. This will ensure ongoing production and the worldwide supply of spare parts. In addition, the areas offer further possibilities for expansion

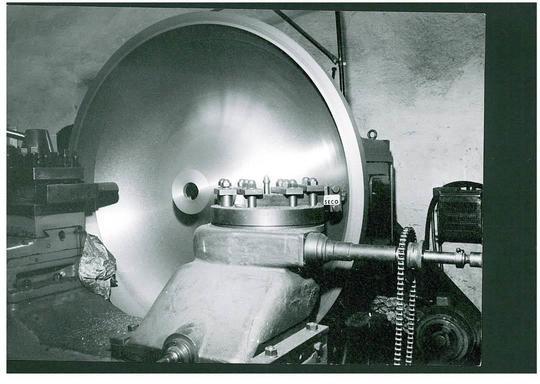

Expanding Production Space

At the ground-breaking ceremony on June 03, 2016 the beginning of the building measures for the new turnery at the production site in Aalen kicks off. The new building including 33 new processing machines is expected to be completed early in 2017.

IFFA 2016

At the IFFA 2016 Seydelmann will be presenting more than 50 machines and 3 production lines at their largest stand so far in an area larger than 1,000 m². The highlights are the new KK 254 AC-6, an emulsifier, equipped with a multi-stage vacuum system at the hopper, pump and cutting set for high quality, improved resource efficiency and increased durability of the product. Next up is our mixer grinder Type AMR 1800. This machine is capable of producing high tonnages of minced meat and minced meat products with very clear cross sections. Another innovation is our universal grinder AV 250 U, a larger version of our popular AU 200U, which can process both fresh meat as well as frozen meat blocks up to -25°C with the same working worm and cutting set. The new version of the table cutter K 20 has been perfected for the use in test kitchens and laboratories. Our two-stage separating set is even better at sorting out hard particles, gristle and tendons now. Similar to how most common cutting sets do it the hard particles are carried into the cutting set center first and then sorted again in a second cutting set. Another way to efficiently sort out hard and foreign particles, especially when it comes to cheese, fruits, vegetables, fish and tofu, is our newly developed Seydelmann separation drum. The material gets pushed through conical holes, hard and foreign particles get removed during this process. All this is done without any wearing parts which helps reduce working costs. In case of a low room height we now offer the possibility to use sliding lids for Seydelmann mixers. They save space and are available in many specifications for maximum customisability.

Extraordinary quality and innovation

Seydelmann is being led by the fifth and sixth generation of the founding family, by the general partners, Peter and Matthias Seydelmann. Peter Seydelmann’s son, Andreas, has been managing the Aalen factory since 2010. The Seydelmann name now stands for outstanding quality and innovation worldwide in German mechanical engineering.

Pressing ahead with innovation

At the IFFA 2013, Seydelmann presents the K 1004 AC-8, the world’s largest Vacuum-Cooking-Cutter with a bowl capacity of 1000 l. Other innovations are the Universal Grinder AU 200 U, which simultaneously chops fresh meat and blocks of frozen meat with temperatures down to –25 °C and the Mixer-Grinder AMR 2500, with innovative worm positioning for extremely quick emptying.

Expansion

Acquisition of more than 8500 m² of additional land for the planned expansion of our premises.

Auto-Command

Presentation of new control units for fully-automated machine operation.

Increased efficiency on production lines

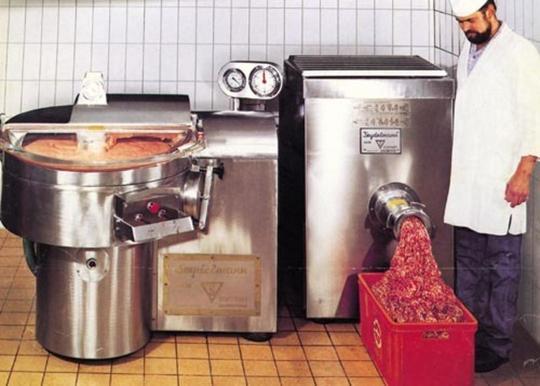

Individual machines are combined with conveyor systems. Users profit from higher hourly output, lower energy requirement, consistent product quality, reduced personnel expense, higher quality assurance, less space requirement, fewer sources of errors and improved hygiene. In the same year, the emulsifier, Konti-Kutter KK 250 AC-6, is launched on the market.

Cutter generation AC-8

Seydelmann launches the first cutters on the market with frequency-controlled, continuous drives. The new maintenance-free generation of cutters stands for the highest knife speeds, diverse applications and low power consumption.

Vacuum mixing

For the first time, Seydelmann presents Vacuum Mixers with 600 to 3500 l hopper capacity.

New benchmark set for robustness and hygiene

All Seydelmann cutters from this point forward are equipped with a solid, stainless steel machine frame.

Grind frozen meat effortlessly

With the installed torque converter, the new Frozen Meat Grinder GW 300 stands up even to the hardest demands.

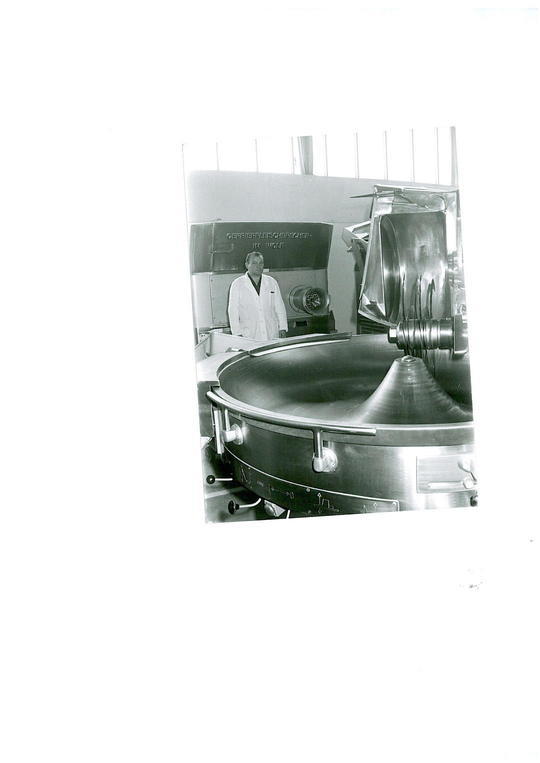

1200 l bowl capacity

1200 l bowl capacity

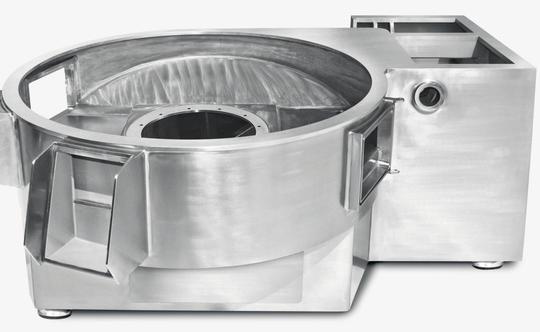

Seydelmann produces the world’s largest cutter to date, with a bowl capacity of 1200 l. The gigantic bowl volume and a previously unachieved degree of automation make the machine into an absolute superlative in mechanical engineering for food processing.

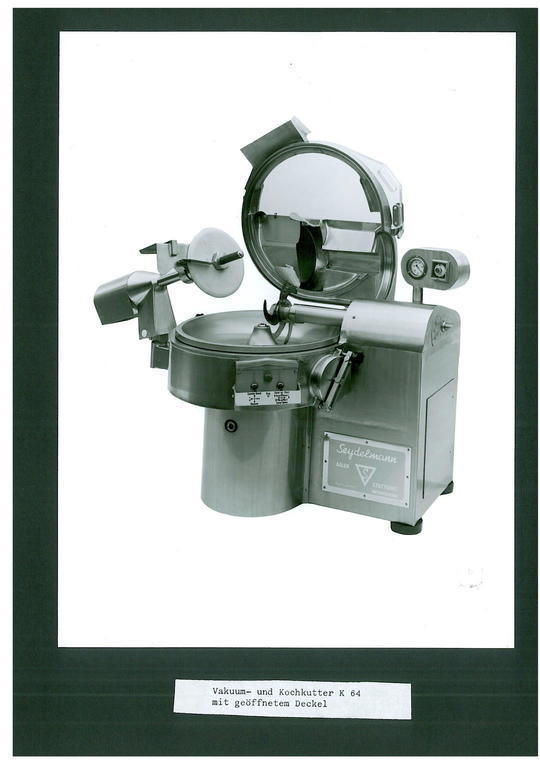

Cutters with a cooking function

Seydelmann launches the first cooking cutter on the market and allows considerable time savings through cutting and cooking in the same work process.

Vacuum cutters

The latest findings in meat technology lead to the development of the vacuum cutter. The brilliant design of the Seydelmann vacuum cutter is patent-protected worldwide.

Separating set for improved meat quality

The market launch of the patented separating sets provides considerable ease of work and time savings with the processing of meat containing sinew. With an innovative technique, the special cutting set sorts out gristle and sinew in the meat during the grinding process and significantly improves the meat quality.

The biggest cutter and a mixer-grinder

Design of the world’s largest cutter at that time, with a 750 l bowl capacity on behalf of a Canadian customer. In the same year, the mixer-grinder is specifically developed for hamburger production for the US market. These innovations are so convincing that the entire large series is delivered overseas.

ULTRA-cutter

The first cutters are built with mixing speeds and ensure considerable ease of work and rationalization.

Robust, long-lasting and hygienic

Seydelmann puts its pioneering role to the test again by introducing the first cutter made from solid stainless steel.

Physical relief for the operator

Seydelmann machines are equipped with hydraulic loading devices.

Seydelmann, fast and long-lasting

The RASANT cutter is the world’s first high-speed multi-speed cutter. Furthermore, stainless steel is used for the cutter cover for the first time, which rapidly establishes itself worldwide.

Shopfitting of butcheries

Seydelmann successfully designs the functional interior of numerous butcheries. The translation of a state-of-the-art technique into creative design appeals to many.

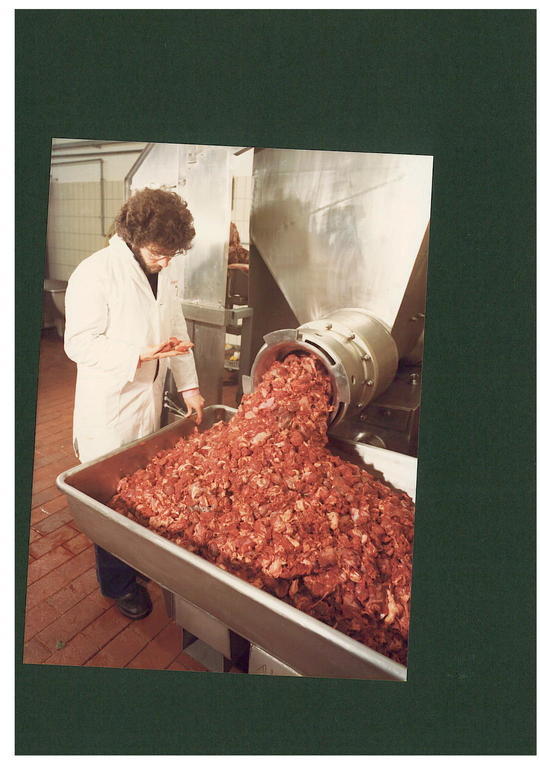

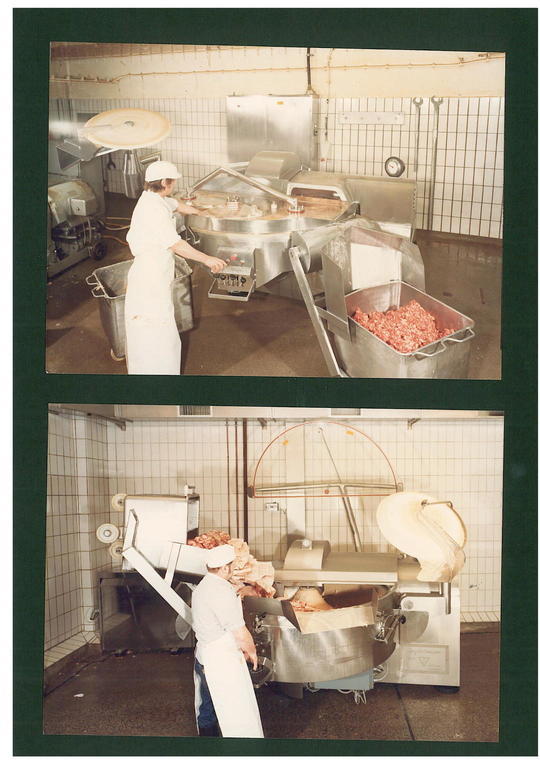

Concentration on cutters and grinders

In addition to machines for butcher shops, prior to the Second World War, Seydelmann produces shopfitting and slaughterhouse fittings, as well as various machine tools, among other things. When supplying the population with food becomes a priority after the end of the war, the company concentrates on the production of cutters and grinders. Under the management of the brothers, Horst and Ludwig Seydelmann, the expansion starts into a global company.

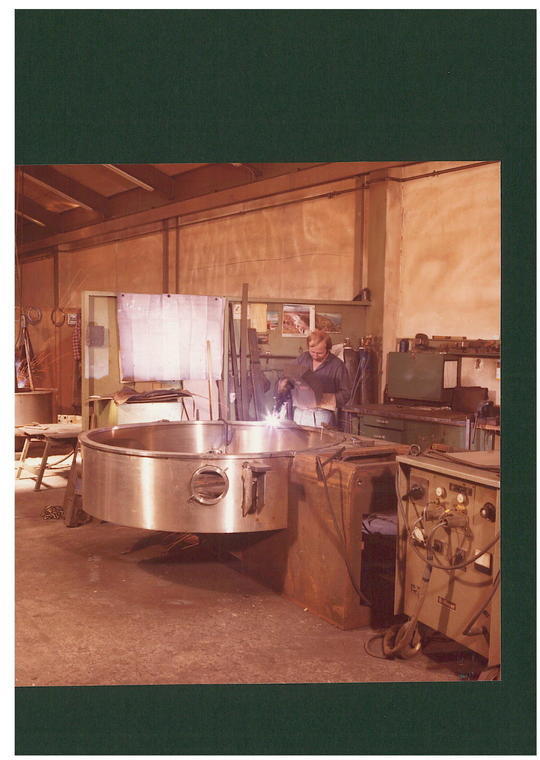

Revolutionary cutting speeds

As a mechanical engineer, Louis Seydelmann the Younger combines the experience of his ancestors with the latest technological findings. He builds some of the first transmission-driven cutters and grinders. The meat chopping technology with chopping blocks, which is the standard at that time, only allows a few cuts per minute. Therefore, the Seydelmann cutter is revolutionary, as it was capable of performing 800 rotations per minute.

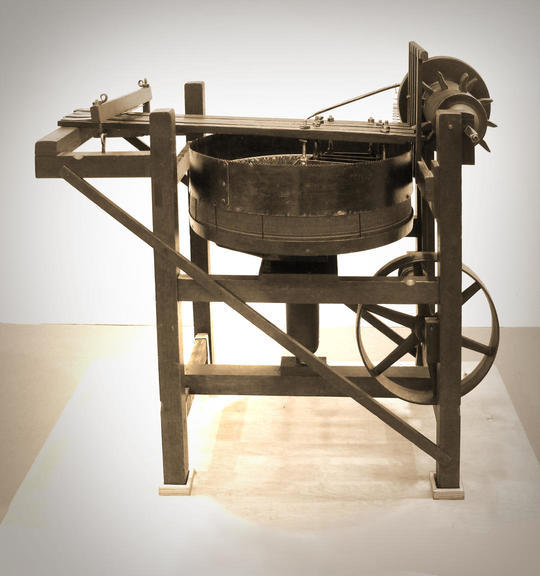

The meat chopping machine

The butchers ask Louis Seydelmann to build a machine that chops meat for sausage production. The stationary water-powered meat chopping machine rapidly establishes itself: The majority of the butchers from the region now bring their meat to Seydelmann to have it chopped. The major success of this first meat chopping machine lays the foundation for the food processing machinery business division.

Seydelmann relocates

Louis Seydelmann takes over his father’s business and relocates the company from the center of Aalen to the outskirts. The good relationship with butchers from Aalen and the surrounding area, which developed due to the close vicinity of the first operating premises to the slaughterhouse, is also maintained after the relocation

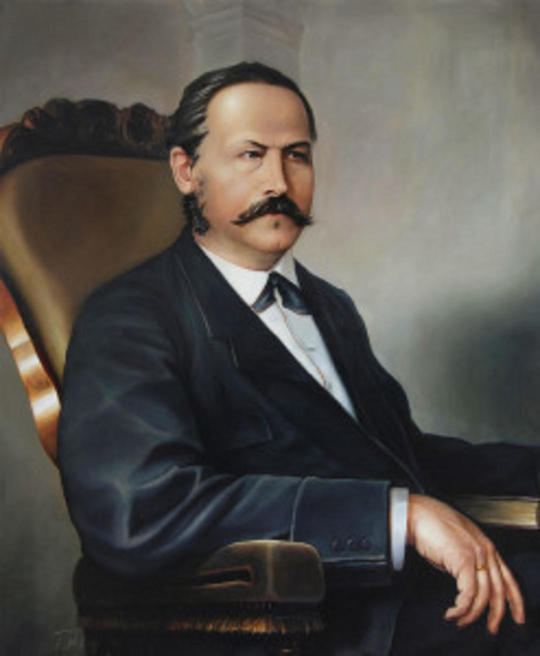

A metal workshop in Aalen

The success story of Maschinenfabrik Seydelmann starts more than 175 years ago in Aalen. In 1843, the company’s founder, Andreas Seydelmann, opens a metal workshop there, where he builds various machines and machine systems for his customers, including steam engines, water pumps for fire fighting, air pumps and water pumps.