Anuga FoodTec 2024 - Review

Maschinenfabrik Seydelmann KG was once again present with a large stand and with its complete machine portfolio - including three complete production lines - and numerous innovations.

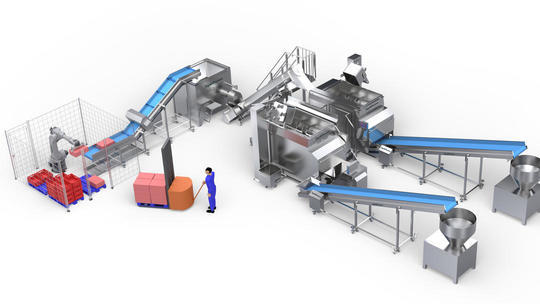

Automation with robot technology

In the food industry, and especially in the production of meat products, automation of production has long been a reality. Processed products are increasingly transported from one production step to the next using appropriate conveyor technology, such as conveyor belts, screw conveyors or pumps, and the raw materials are automatically fed in the required quantities. Only the first step in the chain still requires strenuous manual labor - when emptying the standard transport containers (E2 crates) or when placing blocks of frozen meat.

Seydelmann has been driving the development of the industry for over 180 years now and has also risen to this challenge. By using an industrial robot that meets the strict hygiene requirements in food production, this task can be carried out precisely and around the clock. Precisely matched to the production speed of the machines to be loaded, a higher throughput is achieved while minimizing the risk of contamination and reducing the strain on personnel.

The robot can either automatically load a conveyor belt - possibly with analytics and foreign body/metal detection - or directly feed various machines, such as grinders, cutters or mixers. The empty containers are then stacked back onto a pallet.

Various grippers are precisely matched to frozen meat blocks, E2 crates or other containers - an interchangeable system is possible - and thus ensure gentler handling of the product and container thanks to consistent forces. When emptying E2 crates, they are gripped securely and emptied completely by controlled shaking. The edges are not knocked against metal edges or plates, which prevents plastic from splintering and thus contamination.

The use of robot technology closes a gap in the automation of production, improves work ergonomics, enables higher throughput, reduces the risk of contamination and saves costs.

Maschinenfabrik Seydelmann offers various robot systems including grippers, protective housing and the necessary programming.

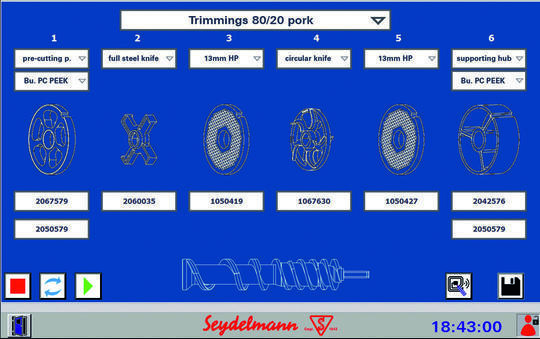

Product and operating safety thanks to visual cutting set recognition

It usually only takes a few minutes to install a grinder cutting set, but there are many sources of error. Adhering to the correct sequence and installing the correct individual parts is of immense importance - for product quality, product safety and for the service life of the cutting set parts and the entire machine.

The visual cutting set recognition system developed by Seydelmann makes it possible to establish a direct link between the products to be processed and the required cutting set, including the correct installation sequence, and to couple this with the machine control system. This means that the machine only starts up if the cutting set stored in the recipe has been installed in the correct installation sequence. This is implemented by means of data matrix codes on the cutting set parts, which must be scanned before installation. The control display, which shows the individual cutting set parts, provides assistance for the operator. Clear and immediate feedback to the operator is guaranteed before any potential damage occurs. Accidental incorrect installation is no longer possible.

Linking the cutting set parameters to the recipe control also ensures that the optimum speeds and other processing parameters are always maintained. Each recipe program has the appropriate cutting set stored and queries all the required parts before starting the machine.

In the case of hole plates, the applied matrix code also serves as an indicator of the wear limit. Once this has been reached, it can no longer be read by the scanner.

Incorrect products or machine damage caused by installation errors can be reliably avoided with visual cutting set recognition and even non-specialist personnel can carry out the installation - resulting in enormous savings potential.

Newly developed machines

The new compact KK 144 c vacuum emulsifier - the little brother of the likewise new KK 254 c - was also on show. Both machines enable emulsifying under vacuum in a very compact design. The advantages include increased shelf life and weight consistency of the end products.

The completely newly developed AE 130 M automatic mixer-grinder combines four functions with a low overall height and small footprint, thereby increasing flexibility in production. It enables mixing and subsequent grinding via the grinding outlet or grinding with subsequent mixing and discharge via the discharge flap. Thanks to the removable mixing unit and large feeder screw, it can also be used purely as an automatic grinder and can also reliably feed whole muscle pieces to the cutting set without any problems. Use as a pure mixer with discharge via the separate discharge flap rounds off the possible applications.

As an option, the new AE 130 M automatic mixer-grinder can be equipped and operated with a manual or pneumatic cutting set, the new Seydelmann cutting drum and a lifting device for E2 crates.

Another new feature is that the AE 130 automatic grinder is equipped with the Seydelmann cutting drum, which has been used successfully for years in industrial grinders with outlet sizes of up to 200 mm. It ensures the efficient separation of hard parts such as pieces of bone, cartilage or tendons. A unique feature is that foreign bodies such as plastic particles or film residues are also reliably separated out without further grinding. Compared to conventional cutting sets, the system consisting of a perforated drum and extended working worm enables a significantly higher throughput and therefore hourly output with a lower temperature input. The system works contact-free and therefore without metal abrasion.

Sophisticated control technology

Another new feature is the Auto-Command 500 control system, which is now standard equipment on all artisinal cutters. In addition to manual operation, it also enables automatic program control of different recipes. The user-friendly design and logic of the display ensures reliable and intuitive operation and is also a response to the shortage of skilled workers in the sector. All relevant data can be clearly read even from a distance and the robust design in protection class IP 69K allows easy and thorough cleaning. Recipes are created via the control unit's touchscreen, while program selection and program start are still carried out using the toggle switches on the machine.

This was just a brief look back at what visitors to Anuga FoodTec were able to see at the Maschinenfabrik Seydelmann stand.

Foundation of a joint sales and service company - Vemag-Seydelmann NL B.V.

Maschinenfabrik Seydelmann KG and Vemag Maschinenbau GmbH are founding a joint sales and service company in the Netherlands.

From March 1, 2024, Seydelmann's sales activities in the Netherlands will be taken over by the new subsidiary Vemag-Seydelmann NL B.V.

Continuity is also ensured for the after-sales area and service in the Netherlands. The seamless transition will take place on 01.07.2024.

It is of the utmost importance that you, our customers, receive optimal support at all times.

Selo B.V. and Maschinenfabrik Seydelmann KG have been working closely together in the Netherlands for over 70 years. During this time, we have successfully implemented numerous projects together in various industries and put well over 300 machines into operation. At the same time, Selo has managed to establish itself very successfully as an independent supplier and manufacturer of process and cooking systems, which has increasingly become its core business. Against this background, a joint approach was found that offers both companies and, above all, their customers even better prospects for the future.

With the founding of the new joint company, Vemag-Seydelmann NL B.V., two strong partners have come together and, in addition to the broader portfolio, can also provide optimum support in planning, advice and service quickly and competently. Maschinenfabrik Seydelmann as a manufacturer of food processing machines and Vemag Maschinenbau as a manufacturer of food filling machines are even more focused on the requirements of customers in the Netherlands

We would like to thank Selo and the entire team for the many years of friendly, reliable and successful cooperation.

Grinders - Visual cutting set detection

It usually only takes a few minutes to install a grinder cutting set, but there are many sources of error. Adhering to the correct sequence and installing the correct individual parts is of immense importance - for product quality, product safety and for the service life of the cutting set parts and the entire machine.

The visual cutting set recognition system developed by Maschinenfabrik Seydelmann KG makes it possible to establish a direct link between the products to be processed and the required cutting set, including the correct installation sequence, and to link this with the machine control system. This means that the machine only starts up if the cutting set stored in the recipe has been installed in the correct installation sequence. This is achieved by means of data matrix codes on the cutting set parts, which must be scanned before installation. The control display, which shows the individual cutting set parts, provides assistance for the operator. Clear and immediate feedback to the operator is guaranteed before any potential damage occurs. Accidental incorrect installation is no longer possible.

Linking the cutting set parameters to the recipe control also ensures that the optimum speeds and other processing parameters are always maintained. Each recipe has the appropriate cutting set stored and queries all the required parts before starting the machine.

In the case of hole plates, the applied matrix code also serves as an indicator of the wear limit. Once this has been reached, it can no longer be read by the scanner.

Incorrect products or machine damage caused by installation errors can be reliably avoided with visual cutting set recognition and even non-specialist personnel can carry out the installation - resulting in enormous savings potential.

This solution will be exhibited at Anuga FoodTec, Hall 9.1, Stand A10.

Full automation in production lines - with robots

In the food industry, and especially in the production of meat products, automation of production has long been a reality. Processed products are increasingly transported from one production step to the next using appropriate conveyor technology, such as conveyor belts, screw conveyors or pumps, and the raw materials are automatically fed in the required quantities. Only the first step in the chain still requires strenuous manual labor - when emptying the standard transport containers (E2 crates) or when placing blocks of frozen meat.

Maschinenfabrik Seydelmann has been driving the development of the industry for over 180 years now and has also risen to this challenge. By using an industrial robot that complies with the strict hygiene requirements in food production, this task can be carried out precisely and around the clock. Precisely matched to the production speed of the machines to be loaded, a higher throughput is achieved while minimizing the risk of contamination and reducing the strain on personnel.

The robot can either automatically load a conveyor belt - possibly with analytics and foreign body/metal detection - or directly feed various machines, such as grinders, bowl cutters or mixers. The empty containers are then stacked back onto a pallet.

Various grippers are precisely matched to frozen meat blocks, E2 crates or other containers - an interchangeable system is possible - and thus ensure gentler handling of the product and container thanks to consistent forces. When emptying E2 crates, they are gripped securely and emptied completely by controlled shaking. The edges are not knocked against metal edges or plates, which prevents plastic from splintering and thus contamination.

The use of robot technology closes a gap in the automation of production, improves work ergonomics, enables higher throughput, reduces the risk of contamination and saves costs.

Maschinenfabrik Seydelmann offers various robot systems including grippers, protective housing and the necessary programming. This solution will be exhibited in a production line at Anuga FoodTec, Hall 9.1, Stand A10.

In the hands of the best

For over 180 years now, Maschinenfabrik Seydelmann KG has been at the forefront of the development, production and distribution of premium quality food processing machines. The innovative and groundbreaking machine program is designed and manufactured by the modern family-owned company in southern Germany. Seydelmann considers itself a globally operating company, which sells its machines in over 150 countries on all five continents. Seydelmann machines are durable and efficiently produce highest quality, thus ensuring competitive advantages for their users.

Customer proximity

Being there for our customers and learning from them allows us to identify and understand their needs and expectations. This type of relationship is the prerequisite for being able to develop, offer and implement solutions that guarantee long-term satisfaction.

Quality

Seydelmann machines are manufactured from the highest quality materials and components and are operated with the latest technology. Since the foundation of the company we plan, design and manufacture all machines in Aalen - "MADE IN GERMANY".

Innovation

Close cooperation with butchers from the region to the international food industry over many decades gives us a deep understanding of everyday production and extensive experience in a wide range of applications.

Service strength

The development of the best possible individual solution as well as a professional installation of the machine are part of the Seydelmann service as well as the possibility of a professional machine instruction with technological advice.