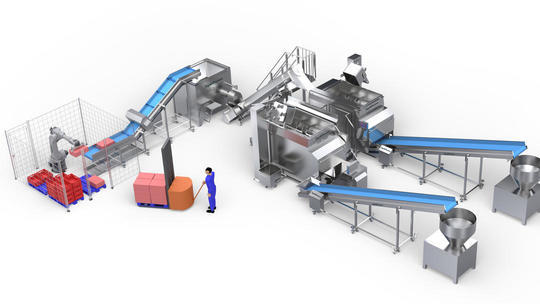

Full automation in production lines - with robots

In the food industry, and especially in the production of meat products, automation of production has long been a reality. Processed products are increasingly transported from one production step to the next using appropriate conveyor technology, such as conveyor belts, screw conveyors or pumps, and the raw materials are automatically fed in the required quantities. Only the first step in the chain still requires strenuous manual labor - when emptying the standard transport containers (E2 crates) or when placing blocks of frozen meat.

Maschinenfabrik Seydelmann has been driving the development of the industry for over 180 years now and has also risen to this challenge. By using an industrial robot that complies with the strict hygiene requirements in food production, this task can be carried out precisely and around the clock. Precisely matched to the production speed of the machines to be loaded, a higher throughput is achieved while minimizing the risk of contamination and reducing the strain on personnel.

The robot can either automatically load a conveyor belt - possibly with analytics and foreign body/metal detection - or directly feed various machines, such as grinders, bowl cutters or mixers. The empty containers are then stacked back onto a pallet.

Various grippers are precisely matched to frozen meat blocks, E2 crates or other containers - an interchangeable system is possible - and thus ensure gentler handling of the product and container thanks to consistent forces. When emptying E2 crates, they are gripped securely and emptied completely by controlled shaking. The edges are not knocked against metal edges or plates, which prevents plastic from splintering and thus contamination.

The use of robot technology closes a gap in the automation of production, improves work ergonomics, enables higher throughput, reduces the risk of contamination and saves costs.

Maschinenfabrik Seydelmann offers various robot systems including grippers, protective housing and the necessary programming. This solution will be exhibited in a production line at Anuga FoodTec, Hall 9.1, Stand A10.