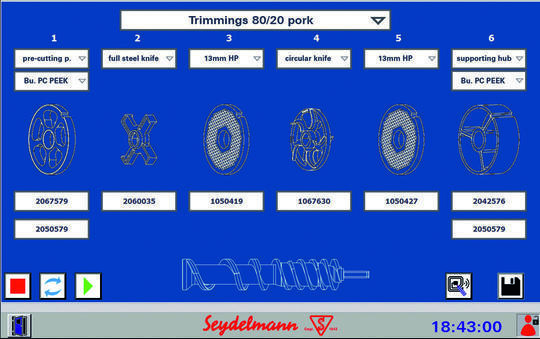

Visual cutting set detection

It usually only takes a few minutes to install a grinder cutting set, but there are many sources of error. Adhering to the correct sequence and installing the correct individual parts is of immense importance - for product quality, product safety and for the service life of the cutting set parts and the entire machine.

The visual cutting set recognition system developed by Maschinenfabrik Seydelmann KG makes it possible to establish a direct link between the products to be processed and the required cutting set, including the correct installation sequence, and to link this with the machine control system. This means that the machine only starts up if the cutting set stored in the recipe has been installed in the correct installation sequence. This is achieved by means of data matrix codes on the cutting set parts, which must be scanned before installation. The control display, which shows the individual cutting set parts, provides assistance for the operator. Clear and immediate feedback to the operator is guaranteed before any potential damage occurs. Accidental incorrect installation is no longer possible.

Linking the cutting set parameters to the recipe control also ensures that the optimum speeds and other processing parameters are always maintained. Each recipe has the appropriate cutting set stored and queries all the required parts before starting the machine.

In the case of hole plates, the applied matrix code also serves as an indicator of the wear limit. Once this has been reached, it can no longer be read by the scanner.

Incorrect products or machine damage caused by installation errors can be reliably avoided with visual cutting set recognition and even non-specialist personnel can carry out the installation - resulting in enormous savings potential.

This solution will be exhibited at Anuga FoodTec, Hall 9.1, Stand A10.