Production Lines

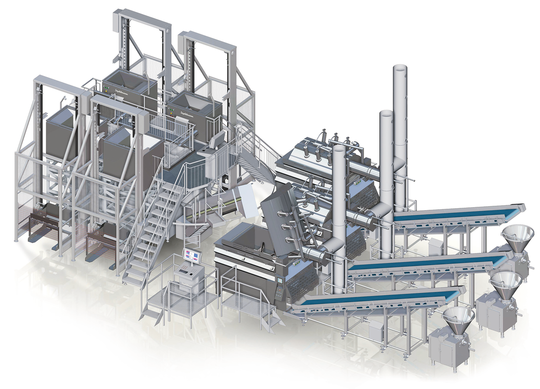

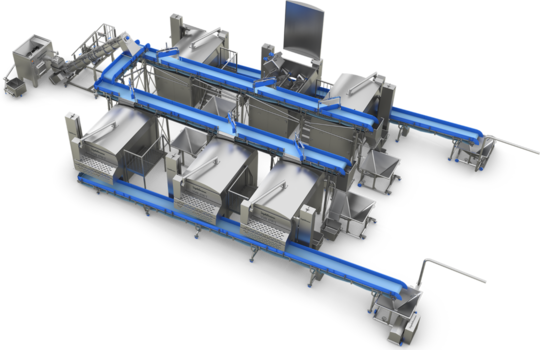

Seydelmann machines can be combined into customized (semi-)automated complete solutions or they can be integrated into existing production processes. In Seydelmann Production Lines, all production steps are performed in the highest quality and efficiency.

Automated production enables significantly higher hourly throughputs and constant product quality with minimal use of energy and personnel. Additional advantages are improved hygiene, fewer sources of errors and gap-free quality assurance and traceability through data recording.

The Seydelmann Production Lines are used in all areas of food processing, e.g. with the production of meat, cheese and vegetable products, as well as soups, sauces and confectionery. Each Line is planned, manufactured and developed in accordance with the individual requirements of the user. Upon request, Seydelmann employees will support the entire planning of production automation with competent, comprehensive advisory.

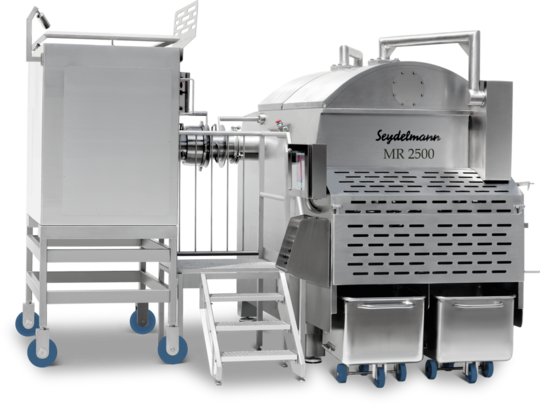

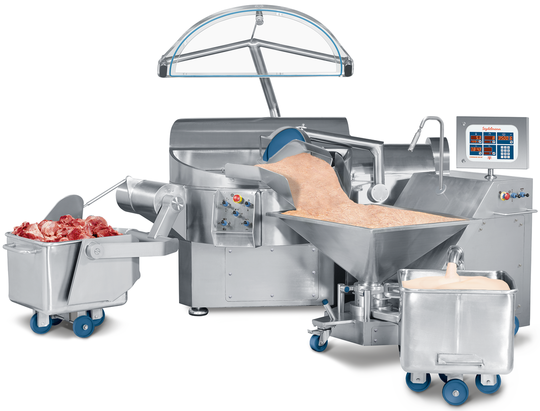

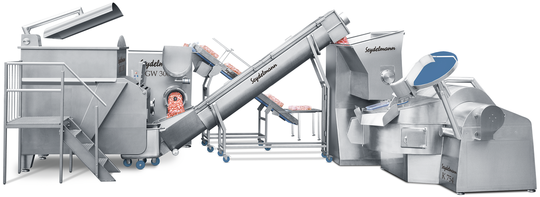

Production Line for ground meat products, hamburger and dry sausage

Weighing feeding belt with scissor lifting tables and X-ray fat analysis, inclined conveyor belt with flights, Universal Grinder AW 300 U, swiveling screw conveyor and three Automatic Mixer Grinders AMR 2500 with liquid gas cooling.

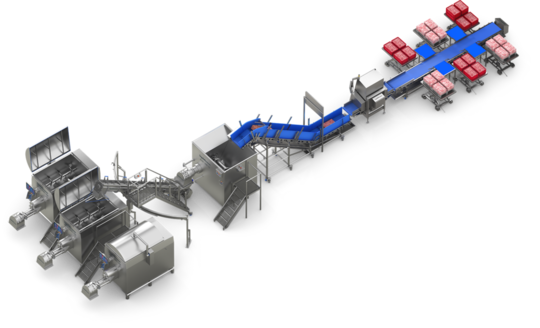

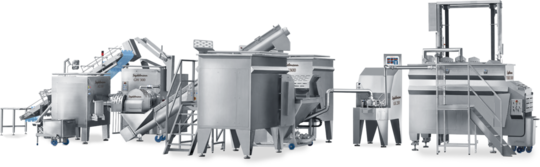

Production Line for chicken nuggets

Two Automatic Grinders AU 200 and two Universal Grinders AU 200 U, each with loading device for large containers, storage hopper with feeding paddle shaft and discharge worm, swiveling screw conveyor, three Vacuum-Mixers VMR 4700 with cooling function, hydraulic lid, and three conveyor belts which transport the material into three fillers.

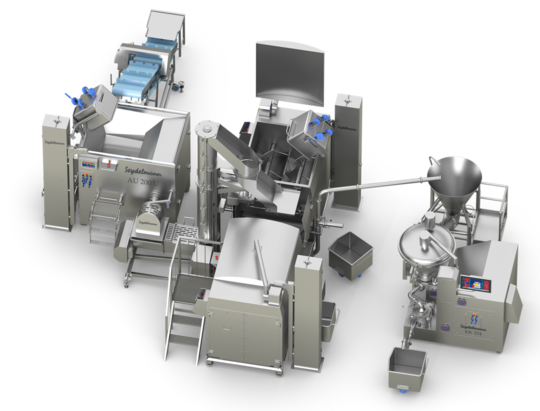

Control of the Production Lines: Central control terminal

The central control terminal ensures the best possible interaction between individual machines in the production line. The Windows-based system control unit is the central interface, from which all machines and their supplemental functions are controlled. All information about individual production steps run together here and are processed further. Production can take place according to stored recipes and fixed, pre-defined values.

As all of the functions, such as the revolutions, vacuum values, gas-flushing, speed of the conveyors and the fat analysis can be monitored and controlled by one person with the central control terminal, personnel costs and potential sources of error are reduced to a minimum. The terminal can be linked with upstream or downstream production steps or it can be integrated into the company network/ERP system of the company.

Due to the possibility of linking a second work station, the entire production can also be monitored outside of the production premises.

Contact us

You are looking for an individual complete solution?

Via the following contact form you can describe your request to us.

We are looking forward to your inquiry!